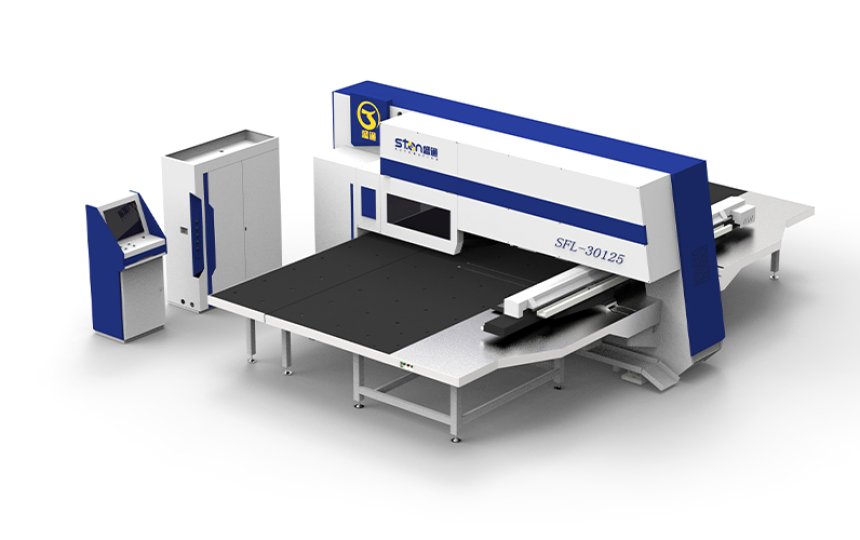

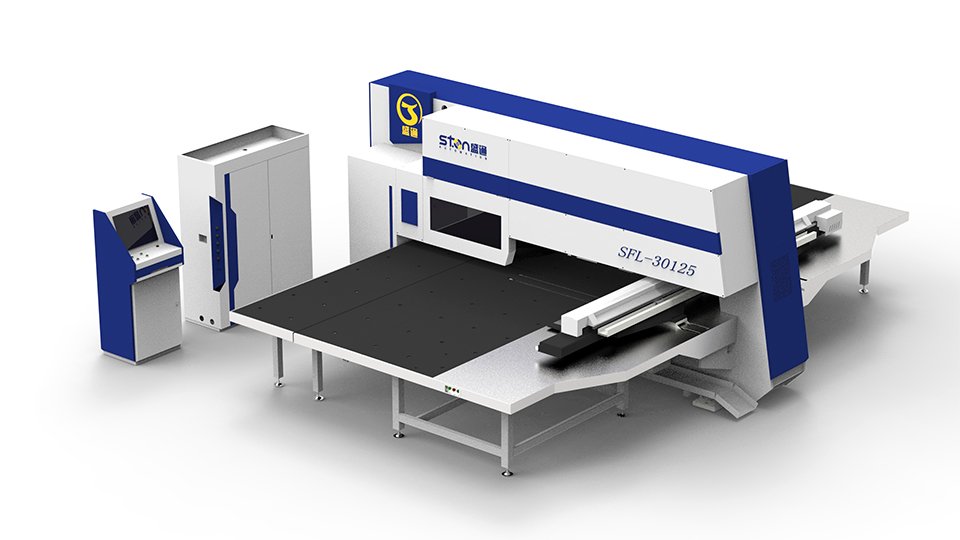

CNC Laser Punching Machine

· Broad Application: Versatile in handling various sheet metal processing needs, adaptable to complex requirements.

· Automation and Customization: Multi-station turret supports customized configurations to meet diverse client needs with a high level of automation.

Inquiry Now

add to cart

··· STON Laser Punching Machine ···

Model: SFL-30125/SFL-30150

Punching Force:30/40tons

| No. | Name | Parameter | Unit | Remark |

| 1 | Punching force | 300 (30) | KN (T) | 1500Nm |

| 2 | Frame structure | "O" type closed frame | ||

| 3 | Maximum plate size for one-time positioning | X-axis 3000 mm | mm | X-axis secondary positioning can process 5000mm |

| Y-axis 1250 mm | mm | |||

| 4 | Maximum plate thickness for processing | 6 | mm | |

| 5 | Maximum diameter for one-time punching | Φ88.9 | mm | |

| 6 | Maximum punching frequency | 1800 | hpm | |

| 7 | Maximum number of punching times | 800 | hpm | |

| 8 | Number of controlled axes | 5 (X, Y, Z, T, C) | Pcs | |

| 9 | Mold form | Long guide 85 series international standard mold | ||

| 10 | Turret station distribution | 16A, 11B, 3C, 2D | Standard | |

| (including rotating stations 1B, 1C) | ||||

| 11 | Repositioning cylinder | 2 | Set | |

| 12 | Maximum feeding speed | X-axis 80 | m/min | |

| Y-axis 80 | m/min | |||

| 13 | Workbench structure | Brush/universal steel ball composite table | Stainless steel edging | |

| 14 | Maximum turret speed | 40 | rpm | |

| 15 | Processing accuracy | ±0.1 | mm | |

| 16 | Laser cutting range | 1250*2500 | mm | |

| 17 | Laser cutting power | 3000 | W | |

| 18 | Laser cutting accuracy | ±0.1 | mm | |

| 19 | Laser Y-axis travel | 1250 | mm | |

| 20 | Laser Z-axis travel | 150 | mm | |

| 21 | Laser cutting blanking size | ≤30 | mm | |

| 22 | Total number of equipment axes | 7 (X, Y, Z, T, C, Z, Y) | Pcs | |

| 23 | Overall dimensions | 6500*5000*2230 | mm |

Overview

A punching and cutting machine is a comprehensive device that integrates the core processing functions of "punching" and "cutting." It is primarily used for rapid, high-precision forming and separation of metal sheets and is widely used in industrial manufacturing. Its core value lies in its integrated design, which reduces process changeovers, improves processing efficiency and precision, and reduces labor and equipment costs.

Learn more

Case Show

-

Composite workpieces

Composite workpieces -

Composite workpieces

Composite workpieces -

Hole Punching

Hole Punching -

Shutter

Shutter

··· check your industry match ···

Component Introduction

-

01.

Machine Body

The machine body is welded from high-strength alloy steel and aged to eliminate internal stress, ensuring long-term deformation resistance. The CNC machining center precision-mills the guide rails, combined with a large-span support structure, ensuring the machine maintains stability during high-speed punching operations, providing a solid foundation for precise machining.

-

02.

Laser Cutting

Equipped with an imported fiber laser generator, the laser power is stable and adjustable over a wide range, easily processing a variety of metal materials, including carbon steel and stainless steel, with thicknesses ranging from 0.2-5mm. Equipped with a high-precision follow-up cutting head, it can sense material thickness changes in real time, ensuring a smooth, burr-free cut surface. Cutting accuracy reaches ±0.1mm, meeting the demands of even the most complex and detailed processing.

-

03.

Turret Punching

The 32-station turret design can simultaneously accommodate multiple dies, enabling rapid switching between punching operations of varying hole diameters and shapes. Its positioning accuracy reaches ±0.01mm. Utilizing a servo drive system, the punching response time is as short as 0.1 seconds per punch, and continuous punching speeds can reach over 800 punches per minute, significantly improving mass production efficiency.

-

04.

Electrical Appliances

Core electrical components are sourced from internationally renowned brands, including Panasonic motors and Schneider circuit breakers, ensuring stable and reliable operation. Equipped with a display screen and a human-machine interface, the unit offers a visual interface for operational flow, graphical programming, and parameter memory, making it easy for even novice operators to quickly master the system. Multiple safety features, including an emergency stop button and overload protection, ensure comprehensive operator safety.

-

05.

Automatic Lubrication System

A centralized automatic lubrication system precisely lubricates key moving parts, such as guide rails and lead screws, according to a pre-set schedule, reducing mechanical wear. The lubrication system features an oil level detection function and automatically issues an alarm when oil is low, preventing equipment failures caused by insufficient lubrication, effectively extending equipment life, and reducing maintenance costs.

-

06.

Work Platform

The laser work platform is constructed from thick, wear-resistant steel with a hardened surface for scratch resistance. The platform measures up to 3000mm x 1500mm, easily accommodating large panels. Combined with an automatic feeder, it enables continuous production. Positioning datums and auxiliary fixture mounting holes are located along the edge of the platform, allowing for quick and easy fixturing of workpieces of varying sizes, improving clamping efficiency.