Servo CNC Punch Press

· Broad Application: Versatile in handling various sheet metal processing needs, adaptable to complex requirements.

· Automation and Customization: Multi-station turret supports customized configurations to meet diverse client needs with a high level of automation.

Inquiry Now

add to cart

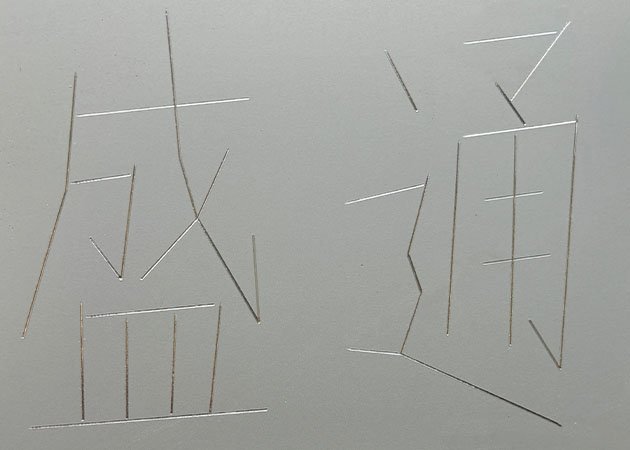

··· STON Servo CNC Turret Punch Press ···

Model: STSK-SF25/STSK-SF30/STSK-SF40

Punching Force:25/30/40tons

| Parameter | Unit | Remarks | ||||||

| Model | STSK-SF25/STSK-SF30/STSK-SF40 | |||||||

| Punching Force | 250(25)/300(30)/400(40) | KN(T) | ||||||

| Frame Structure | O-Type Closed Frame | |||||||

| Max Sheet Size for Single Positioning | X-Axis2500 Y-Axis1250/1500/2000/2500 | mm | Customizable to Non-Standard | |||||

| Max Sheet Thickness | 6 | mm | Based on Sheet Type | |||||

| Max Punching Diameter in a Single Stroke | φ88.9 | mm | Customizable to Non-Standard | |||||

| Max Punching Frequency | 1800 | hpm | ||||||

| Max Punching Hits | 800 | hpm | ||||||

| Number of Control Axes | 5(X、Y、T、C、R) | piece | ||||||

| Die Type | Long Guide 85 Series International Standard Die | |||||||

| Turret Station Distribution | 16A、11B、3C、2D(Including Rotary Stations1B、1C) | Standard | Customizable to Non-Standard | |||||

| Repositioning Cylinder | 2 | set | ||||||

| Number of Clamps | 3 | piece | ||||||

| Max Feeding Speed | X-Axis90 Y-Axis80 | m/min | ||||||

| Worktable Structure | Brush and Universal Ball Composite Work Surface | |||||||

| Max Turret Speed | 40 | rpm | ||||||

| Processing Precision | ±0.1 | mm | ||||||

| Max Load Capacity | 150 | Kg | ||||||

| Total Power Consumption | 5 | Kw | ||||||

| Air Source Pressure | 0.55 | Mpa | ||||||

| Power Supply | 380±5% | V | ||||||

| Overall Dimensions | 5000/5500/6500/7800×5200×2100 | mm | ||||||

Overview

A punching and cutting machine is a comprehensive device that integrates the core processing functions of "punching" and "cutting." It is primarily used for rapid, high-precision forming and separation of metal sheets and is widely used in industrial manufacturing. Its core value lies in its integrated design, which reduces process changeovers, improves processing efficiency and precision, and reduces labor and equipment costs.

Learn more

Punching Demonstrations

Industry Applieation Cases

-

Furniture Side Panel

Furniture Side Panelwatch the process

-

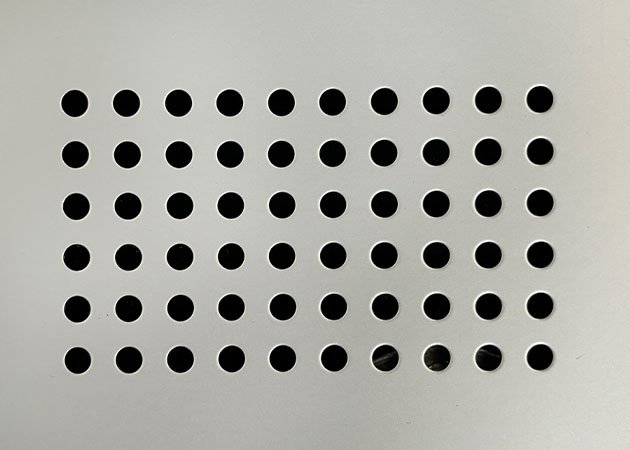

Patterned Curtain Wall

Patterned Curtain Wallwatch the process

-

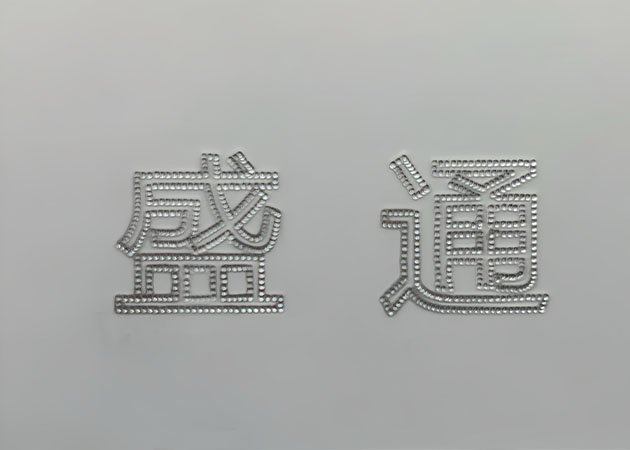

STON Sample

STON Samplewatch the process

-

Medical equipment

Medical equipmentwatch the process

Case Show

-

AC Unit Enclosure

AC Unit Enclosure -

BBQ grill

BBQ grill -

Building curtain wall

Building curtain wall -

Highway Sound Barrier

Highway Sound Barrier -

Air conditioner

Air conditioner -

Aluminum Cladding Panel

Aluminum Cladding Panel -

Cabinet Enclosure

Cabinet Enclosure -

Filing cabinet

Filing cabinet

··· check your industry match ···

Component Introduction

-

01.

CNC System

•Stable Communication and Control: Imported motherboard and Panasonic RTEX bus servo unit, utilizing a full-closed loop transmission, ensuring precise, fast control signals with minimized signal loss.

•Efficient Data Transmission: RTEX bus enables seamless data exchange and real-time monitoring with strong anti-interference capabilities.

•Upgradability and Compatibility: Supports software upgrades and is compatible with various loading/unloading systems, ensuring flexibility for future business expansion.

-

02.

Programming System

•User-Friendly: Graphical display of processing programs reduces errors, compatible with G-code, CAD, and CNCKad systems, supporting multi-axis linkage for enhanced flexibility and efficiency.

•Parameter Management: Automatically matches and stores parameters for easy recovery, significantly improving operational efficiency.

-

03.

Frame Structure

•High-Strength Design: The “O”-type closed structure, analyzed using finite element methods, ensures high stability and vibration resistance.

•Precision Machining: High-temperature annealing eliminates internal stress, and key components such as guide rails and lead screws are machined in one fixture, ensuring assembly accuracy.

-

04.

Punching Assembly

•Efficient and Stable: Proprietary sealed punching assembly prevents leaks and is equipped with a high-power servo direct drive motor, improving punching response speed.

•Smart Adjustment: The swing punching control automatically adjusts swing angles based on the process, enhancing punching efficiency. The oil-cooling system ensures stable operation under extreme conditions.

-

05.

Transmission Mechanism

•High Precision and Stability: The turret undergoes rigorous testing to ensure flatness, concentricity, and parallelism. Dual-chain transmission enhances stability.

•Precise Positioning: Upgraded cylinder positioning design reduces turret side sleeve wear, and the worm gear transmission system provides fast, precise, and quiet performance with high durability.

-

06.

Feeding System

•High-Precision Feeding: Integrated X and Y-axis guide rails and lead screws ensure precise feeding. Pneumatic clamps are easy to operate and provide stable gripping and feeding.

•Lubrication System: Multi-point automatic lubrication ensures full lubrication of all moving parts, reducing wear.